“How Are We Doing?” Efficiency, Utilization, and Productivity

In business, knowing how we are performing in relation to our competition is vital. Internally we want to know if we are using resources effectively and getting the most out of what we have. Efficiency and Productivity are two calculations that are fundamental to the success of any organization. While the calculations are simple, choosing what measures to use and collecting the necessary data requires a thorough understanding of your industry.

To calculate Efficiency you will have to first decide what to use as a base for comparison. Does your company already have a “target” of some kind? Like total units produced? If so then you can compare everything to that. Once you have that, there are a couple of basic formulas that can be used:

Efficiency = Actual Output/Effective Capacity X 100%

Utilization = Actual Output/Design Capacity X 100%

Design Capacity is the maximum output achieved under ideal conditions. Effective Capacity is always less than Design Capacity because of factors such as the need for maintenance, lunch breaks, coffee breaks, and other problems in scheduling. Actual Output cannot exceed Effective Capacity because of machine breakdowns, shortages of materials, and quality problems. Capacity then refers to an upper limit on the rate of output. Consider the following example:

“A computer repair service center has a Design Capacity of 80 repairs per day. Its Effective Capacity is 64 repairs per day but Actual Output is only 62 repairs per day. Calculate Efficiency and Utilization.”

Efficiency = 62/64 X 100% = 96.875%

Utilization = 62/80 X 100% = 77.5%

In selecting a measure of capacity, it is important to choose one that does not need to be updated. Dollar amounts are often a poor indicator of true capacity due to price changes. No single measure of capacity will be appropriate in every situation. Rather the measure of capacity must be tailored to the situation. The following are examples:

Closely related to the concept of Efficiency is Productivity. The following formula illustrates Multifactor Productivity:

Multifactor Productivity = Output/(Labor+Materials+Overhead)

Productivity measures are useful on a number of levels. For an individual or department productivity can be used to track performance over time. This allows managers to evaluate performance and decide if more improvements are needed. Productivity measures can also be used to appraise the performance of an entire industry or even a country as a whole. These measures are called aggregate measures. Determine the Multifactor Productivity for the following:

Output: 7,040 units

Labor: $1,000

Materials: $520

Overhead: $2,000

Multifactor Productivity = 7,040/($1,000+$520+$2,000) = 2 units per dollar

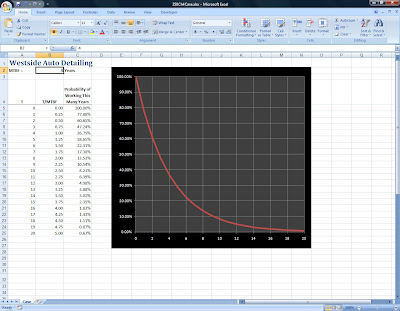

In essence productivity serves as a scorecard of the effective use of resources. Business leaders are concerned with productivity as it relates to competiveness. If two firms both have the same level of output but one requires less input because of higher productivity that one will be able to charge a lower price and increase its market share. Or else that firm may want to charge the same price and earn a greater profit. Government leaders are concerned with national productivity figures because of the relationship between productivity and standard of living. It is easy to overlook the importance of productivity figures--there’s nothing glamorous about them to get our attention. High productivity and high standards of living typically go hand in hand. Productivity figures for all sectors of the US economy may be found at the Bureau of Labor Statistics web site: www.bls.gov The following graph shows multifactor productivity for Manufacturing (Series ID: MPU9900012) from 1987 to 2009:

Data from the website may be downloaded in Excel format which makes it easy to analyze. Given the availability of computers and abundance of information, there is no reason that a decision-maker should not be aware of how their organization is performing.

To calculate Efficiency you will have to first decide what to use as a base for comparison. Does your company already have a “target” of some kind? Like total units produced? If so then you can compare everything to that. Once you have that, there are a couple of basic formulas that can be used:

Efficiency = Actual Output/Effective Capacity X 100%

Utilization = Actual Output/Design Capacity X 100%

Design Capacity is the maximum output achieved under ideal conditions. Effective Capacity is always less than Design Capacity because of factors such as the need for maintenance, lunch breaks, coffee breaks, and other problems in scheduling. Actual Output cannot exceed Effective Capacity because of machine breakdowns, shortages of materials, and quality problems. Capacity then refers to an upper limit on the rate of output. Consider the following example:

“A computer repair service center has a Design Capacity of 80 repairs per day. Its Effective Capacity is 64 repairs per day but Actual Output is only 62 repairs per day. Calculate Efficiency and Utilization.”

Efficiency = 62/64 X 100% = 96.875%

Utilization = 62/80 X 100% = 77.5%

In selecting a measure of capacity, it is important to choose one that does not need to be updated. Dollar amounts are often a poor indicator of true capacity due to price changes. No single measure of capacity will be appropriate in every situation. Rather the measure of capacity must be tailored to the situation. The following are examples:

Closely related to the concept of Efficiency is Productivity. The following formula illustrates Multifactor Productivity:

Multifactor Productivity = Output/(Labor+Materials+Overhead)

Productivity measures are useful on a number of levels. For an individual or department productivity can be used to track performance over time. This allows managers to evaluate performance and decide if more improvements are needed. Productivity measures can also be used to appraise the performance of an entire industry or even a country as a whole. These measures are called aggregate measures. Determine the Multifactor Productivity for the following:

Output: 7,040 units

Labor: $1,000

Materials: $520

Overhead: $2,000

Multifactor Productivity = 7,040/($1,000+$520+$2,000) = 2 units per dollar

In essence productivity serves as a scorecard of the effective use of resources. Business leaders are concerned with productivity as it relates to competiveness. If two firms both have the same level of output but one requires less input because of higher productivity that one will be able to charge a lower price and increase its market share. Or else that firm may want to charge the same price and earn a greater profit. Government leaders are concerned with national productivity figures because of the relationship between productivity and standard of living. It is easy to overlook the importance of productivity figures--there’s nothing glamorous about them to get our attention. High productivity and high standards of living typically go hand in hand. Productivity figures for all sectors of the US economy may be found at the Bureau of Labor Statistics web site: www.bls.gov The following graph shows multifactor productivity for Manufacturing (Series ID: MPU9900012) from 1987 to 2009:

Data from the website may be downloaded in Excel format which makes it easy to analyze. Given the availability of computers and abundance of information, there is no reason that a decision-maker should not be aware of how their organization is performing.

Comments